High-speed Steam Engine on:

[Wikipedia]

[Google]

[Amazon]

High-speed steam engines were one of the final developments of the

High-speed steam engines were one of the final developments of the

High-speed steam engines were one of the final developments of the

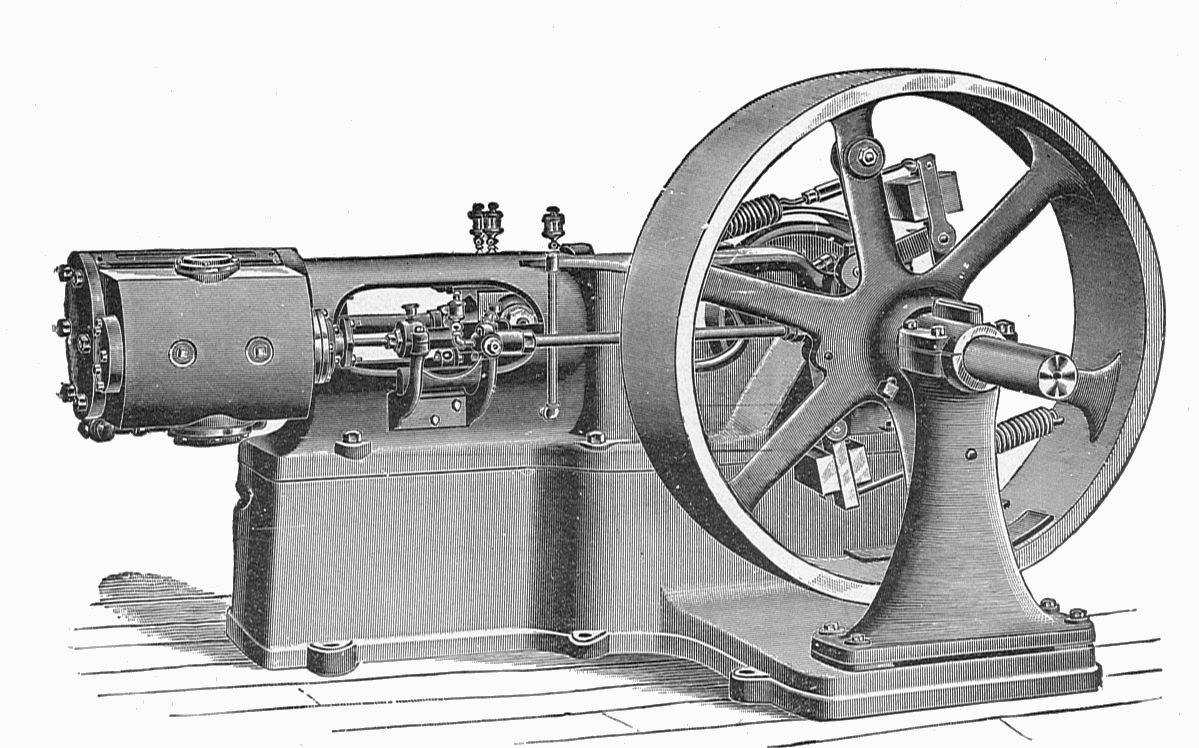

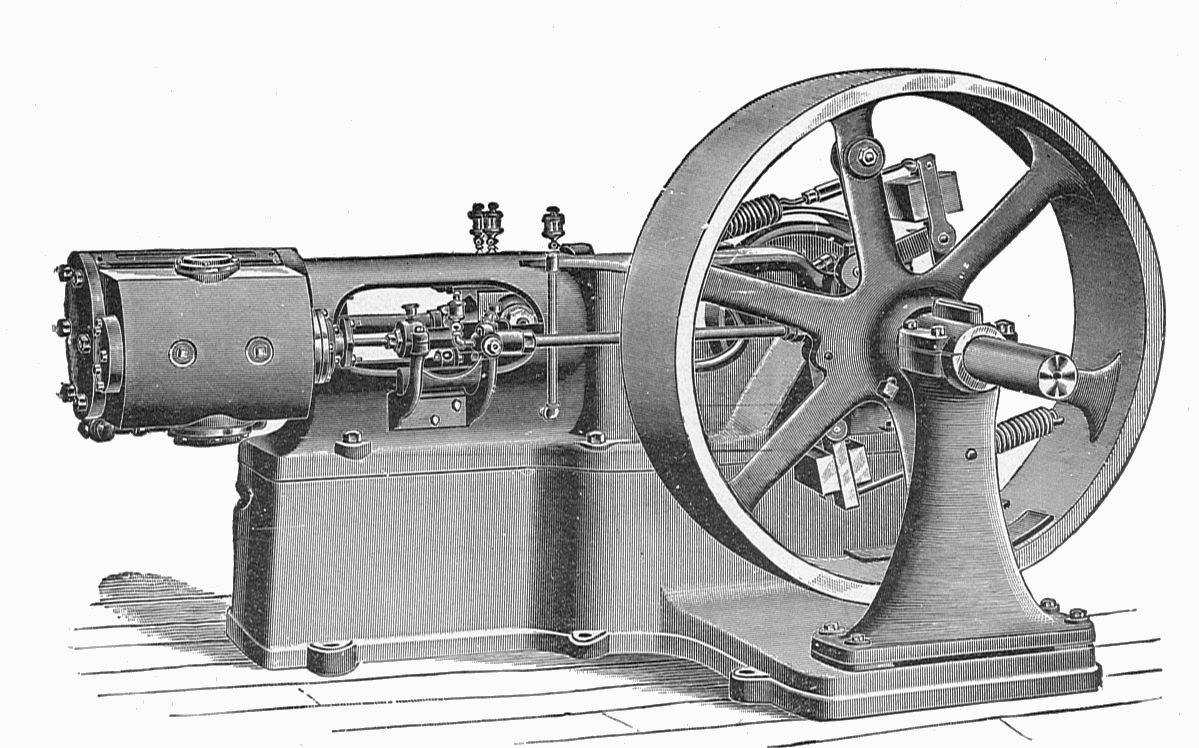

High-speed steam engines were one of the final developments of the stationary steam engine

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars ...

. They ran at a high speed, of several hundred rpm,, 400 to 1,200 rpm which was needed by tasks such as electricity generation.

Defining characteristics

They have two primary characteristics: * High speed. : This is sufficient to drive a smalldynamo

file:DynamoElectricMachinesEndViewPartlySection USP284110.png, "Dynamo Electric Machine" (end view, partly section, )

A dynamo is an electrical generator that creates direct current using a commutator (electric), commutator. Dynamos were the f ...

directly, rather than needing a step-up drive by belts.

* Accurate speed regulation.

: Generation by dynamo requires a stable rotation speed for a stable output voltage, even when the load changes. When an alternator

An alternator is an electrical generator that converts mechanical energy to electrical energy in the form of alternating current. For reasons of cost and simplicity, most alternators use a rotating magnetic field with a stationary armature.Go ...

was being driven, the output frequency also depended upon a stable rotation speed.

These also resulted in a number of secondary characteristics. Although these were not defining to the type, or were always the case, they were recognisably common:

* Improved lubrication, as required by their high speed.

: This often used an enclosed crankcase

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block.

Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/a ...

with an oil sump and lubrication by 'splash

Splash or Splash! or The Splash may refer to:

Common meanings

* Splash (fluid mechanics), sudden disturbances on the surface of water

Entertainment

* ''Splash'' (film), a 1984 fantasy film starring Tom Hanks and Daryl Hannah

** ''Splash, Too'' ...

' or by ring oiler

A ring oiler or oil ring is a form of oil-lubrication system for bearings.

Ring oilers were used for medium-speed applications with moderate loads, during the first half of the 20th century. These represented the later years of the stationary s ...

s. Some went so far as to have engine-driven oil pumps and a circulation system

The blood circulatory system is a system of organs that includes the heart, blood vessels, and blood which is circulated throughout the entire body of a human or other vertebrate. It includes the cardiovascular system, or vascular system, tha ...

.

* Small, rigid cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

frames, so that they did not require the large stationary engine's usual complex masonry

Masonry is the building of structures from individual units, which are often laid in and bound together by mortar; the term ''masonry'' can also refer to the units themselves. The common materials of masonry construction are bricks, building ...

foundations.

* Single-acting cylinder

In mechanical engineering, the cylinders of reciprocating engines are often classified by whether they are single- or double-acting, depending on how the working fluid acts on the piston.

Single-acting

A single-acting cylinder in a reciprocat ...

s.

: As the crankcase became more important for lubrication, the layout was simpler if steam pressure was only applied to one side of the cylinder. This has a second advantage: as the steam's force is now only on one side of the piston, the force on the bearings will still vary through the stroke, but it no longer reverses its direction. This reduces the effects of any bearing slop at high speed.

High speed was not needed for electrical power generation in the largest citywide plants. As these plants were necessarily large, they could also use large-diameter dynamos with many pole pieces. This gave the necessary linear speed (in poles passed / time) for a lower rotational shaft speed.

These engines were produced with either simple

Simple or SIMPLE may refer to:

*Simplicity, the state or quality of being simple

Arts and entertainment

* ''Simple'' (album), by Andy Yorke, 2008, and its title track

* "Simple" (Florida Georgia Line song), 2018

* "Simple", a song by Johnn ...

or compound

Compound may refer to:

Architecture and built environments

* Compound (enclosure), a cluster of buildings having a shared purpose, usually inside a fence or wall

** Compound (fortification), a version of the above fortified with defensive struct ...

operating cycles. Smaller examples were usually simple, as the difficulties of achieving good regulation outweighed the efficiencies of compounding. High-speed engines did develop a reputation for profligacy. For larger engines the fuel cost savings were worthwhile and compound designs such as the Willans engine

The Willans engine or central valve engine was a high-speed stationary steam engine used mainly for electricity generation around the start of the 20th century.

Willans' engine was one of the best-known examples of the steeple compound engine. T ...

were used.

They also used a wide range of valves. Examples with either slide or piston valves were common. Multi-cylinder single-acting engines typically shared one piston valve between two cylinders, either between the cylinders or horizontally above them.

The valvegear driving these valves was usually simple, a single eccentric designed only to run at one speed, in one direction, for a fairly constant load. Although these engines were contemporaneous with sophisticated and efficient valvegears such as the Corliss, these trip valves were incapable of working quickly enough.

"Automatic" engines

A key requirement for the high-speed steam engine was accurate control of a constant speed, even under a rapidly changing load. Although the control of steam engines via acentrifugal governor

A centrifugal governor is a specific type of governor with a feedback system that controls the speed of an engine by regulating the flow of fuel or working fluid, so as to maintain a near-constant speed. It uses the principle of proportional cont ...

dates back to Watt

The watt (symbol: W) is the unit of power or radiant flux in the International System of Units (SI), equal to 1 joule per second or 1 kg⋅m2⋅s−3. It is used to quantify the rate of energy transfer. The watt is named after James Wa ...

, this control was inadequate. These early governors operated a throttle

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction.

An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' ...

valve to control the flow of steam to the engine. This gives an inadequately responsive control for the constant speed needed for electricity generation.

The solution developed for high-speed steam engines was the "automatic" governor. Rather than controlling the flow rate of steam, it controlled the timing or 'cut-off

A cut-off, battle jacket, battle vest or kutte in heavy metal subcultures, is a type of vest or jacket which originated in the U.S. military, specifically the Army Air Corps, where pilots and other aviation personnel would collect patches or o ...

' of the inlet valves. This governor was interspersed between the crankshaft and the eccentric driving the valve gear. It was often made as part of the engine's flywheel. A centrifugal bob weight in the governor moved out against a spring with increasing speed. This caused the eccentric's position to shift relative to the crank, changing the valve timing and causing an early cut-off. As this control acted directly at the cylinder port, rather than through a long pipe from a throttle valve, it could be very fast-acting.

Lubrication

Enclosed crankcase splash lubrication

Splash lubrication

Splash lubrication is a rudimentary form of lubrication found in early engines. Such engines could be external combustion engines (such as stationary steam engines), or internal combustion engines (such as petrol, diesel or paraffin engines). ...

: Lubrication of the first high-speed engines, such as the ''Ideal'' (an open-crank horizontal engine), were lubricated by a development of the oil cup systems previously widespread on medium-speed stationary engines. Oil cups and multi-point lubricators could oil shaft bearings well enough and a single sight-glass could be observed by even the most careless engine driver or oiler. The difficulty was that on high-speed engines, oilers could no longer be mounted on moving parts, such as the crosshead or connecting rod. Any oil reservoir here would be churned around by the movement and such a necessarily small reserve might also be inadequate incapacity for an engine doing so much work in a small space. More care was thus given to the thoroughness of oiling, and moving parts such as the crankpin were fed by drillings through the crankshaft from oil supplies that were rotating but not moving, such as the main bearings. Centrifugal force was also used to distribute the oil. It was usual that high-speed engines would have only one or two lubricators, so that engine tending was a simpler task and less prone to breakdowns from simple carelessness and running a lubricator dry.

Single-acting engines

As speeds increased, the high-speed engine evolved towards its developed form of the multi-cylinder vertical engine with an enclosedcrankcase

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block.

Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/a ...

. There was also a tendency to use single-acting pistons. This had two advantages, the lubrication could be provided by a generous 'splash' system within the crankcase that also helped with cooling, and secondly that the forces in a single-acting engine always act in the same way, as a compression force along the piston rod and connecting rod. This meant that even if a bearing's clearances were relatively slack, the bearing was always held tight. Slack, and thus free-running, bearings could be accepted. An example of such an engine would be the twin-cylinder ''Westinghouse'' engines. These engines used a trunk piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tigh ...

, as used for internal combustion engines today, where there is no separate crosshead and the gudgeon pin of the connecting rod is moved up within the piston itself. This provides a very compact layout, but obviously requires a single-acting piston. The main crankshaft bearings of this engine were provided with separate oilers that drained into the crankcase sump. It was recognised that the crankcase oil would become contaminated with water from condensed steam and blow-by from the pistons. A valve was provided for draining this collected condensate off from beneath the oil in the bottom of the deep sump.

Double-acting engines and the invention of pressure lubrication

The important concept of pressure lubrication of engine bearings began with high-speed steam engines and is now a vital part ofinternal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combus ...

s. This is both reliable as a lubrication system and also allows the use of hydrostatic bearing

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing flu ...

s ('oil wedge') that can support greater loads. The first patents for this were issued to Belliss & Morcom in 1890, from the work of their draughtsman Albert Charles Pain. Belliss & Morcom preferred double-acting cylinders, so as to produce the smallest possible engines for a given power; one of their major markets, like Peter Brotherhood

Peter Brotherhood (1838–1902) was a British engineer. He invented the Brotherhood engine used for torpedoes as well as many other engineering products.

With his son he built a large engineering business in London bearing his name, Peter Brother ...

, was in supplying generator sets to the Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against F ...

for use in the confines of a warship engine room. The difficulty of a double-acting engine was that the direction of the forces in the connecting rod now reverses between compression and tension, so that the bearing clearances must be made tighter to avoid any rattling. Belliss and Morcom developed a two-cylinder engine of 20 bhp at 625 rpm that used a small separate oil pump to feed oil under pressure to the crank bearings, through long drilled holes in the crankshaft. This provided reliable lubrication and cooling and the pressure of the oil film was sufficient to allow the use of double-acting engines with adequate clearance to provide free running.

See also

*Willans engine

The Willans engine or central valve engine was a high-speed stationary steam engine used mainly for electricity generation around the start of the 20th century.

Willans' engine was one of the best-known examples of the steeple compound engine. T ...

* Uniflow engine

* Steam motor

A steam motor is a form of steam engine used for light locomotives and light self-propelled motor cars used on railways. The origins of steam motor cars for railways go back to at least the 1850s, if not earlier, as experimental economizations for ...

, the application of the high-speed engine principles to steam locomotives

Notes

References

Further reading

* {{steam engine configurations, state=collapsed Stationary steam engines Steam engines by type